phone : 317-887-6352

Menu

Specification Notes:

Warranty Document

Warranty Document

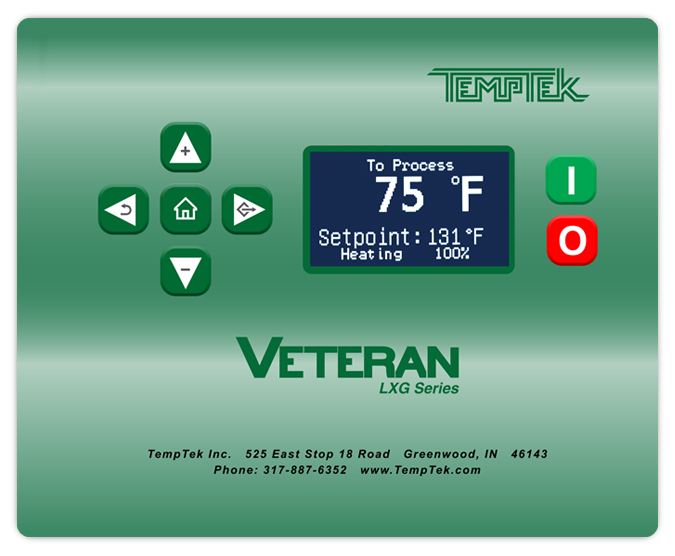

Model VT-2500-LXT shown. Image shown is typical. Actual unit appearance will vary according specifications and options.

Product innovation and improvement is our constant goal. All features and specifications are subject to change without notice or liability.

Products are assembled in the United States of America.

©2025 TEMPTEK, INC

Privacy PolicyNow